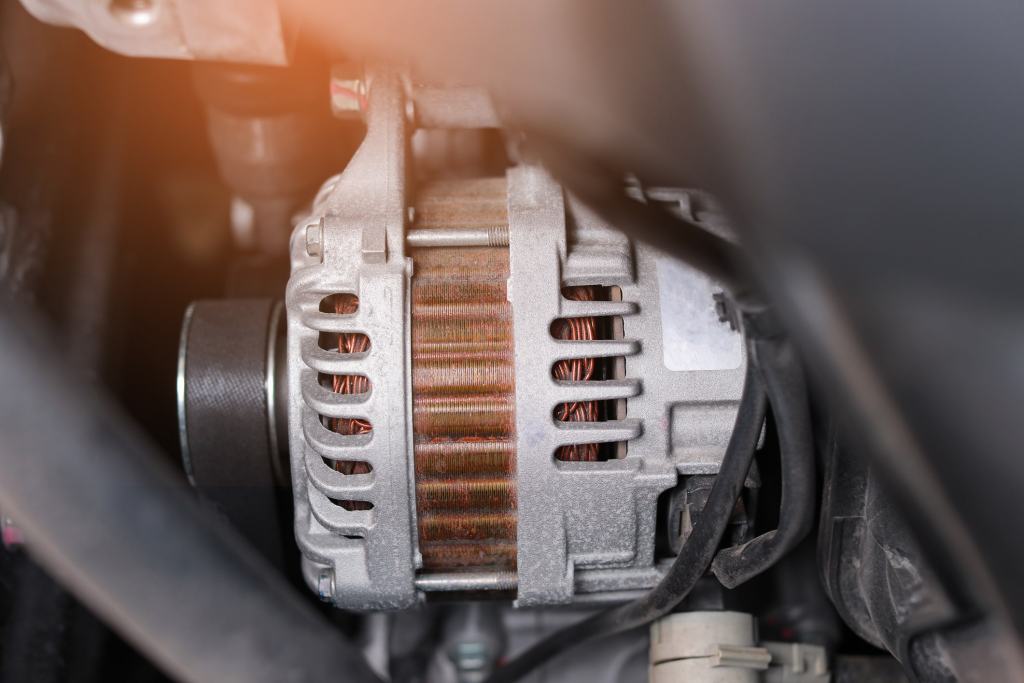

Electric motors are an indispensable part of modern industry and daily life. They are used to perform all kinds of mechanical work, from powering the motion of automobiles to various applications in factories. The fundamental operating principle of electric motors relies on electromagnetism and the use of a magnetic field. One of the critical components inside these motors is the enamel-coated coil wires.

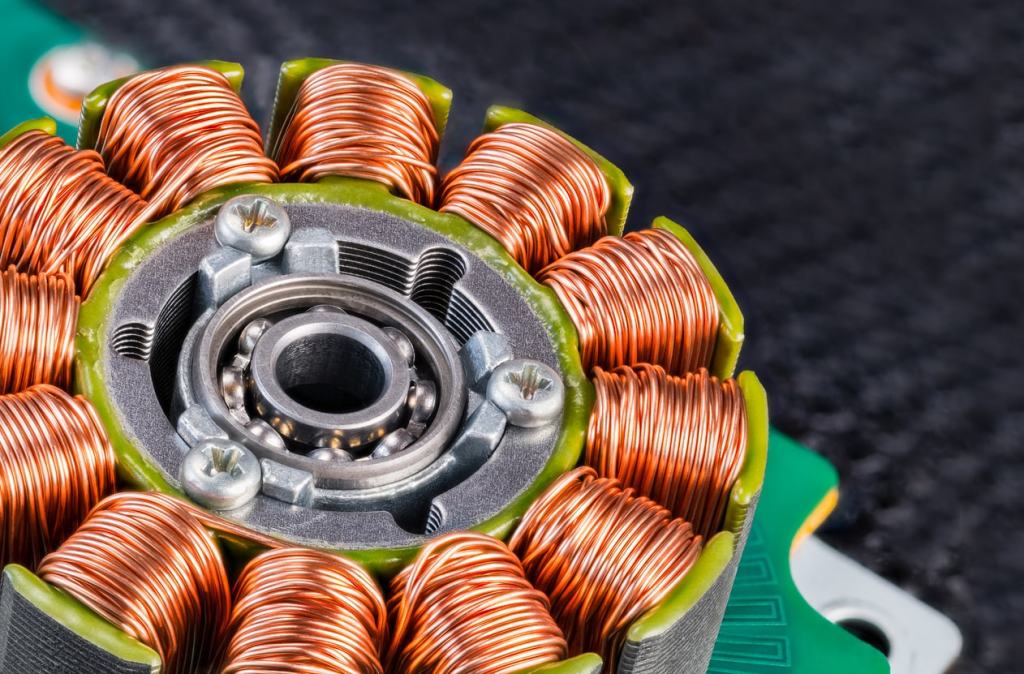

Enamel-coated coil wires are vital elements that facilitate the creation of a magnetic field between the stator and rotor inside the motor. These wires are made of conductive materials like copper or aluminum, and each wire is coated with insulation known as enamel. The enamel coating insulates the wires and prevents short circuits between them, allowing electrical current to be safely conducted.

The operating principle of electric motors is centered around generating a magnetic field and applying electrical current to the coil wires within this field. This magnetic field is produced by the stator, and the coil wires on the rotor rotate within the magnetic field. Enamel-coated wires transmit electrical current to the coils on the rotor, causing it to spin. This rotational motion results in the electric motor performing mechanical work.

Enamel-coated coil wires enhance the reliability of electric motors by preventing short circuits between the wires and contribute to the motors’ efficiency. They reduce energy loss and enable electric motors to generate more power with less wastage.

In conclusion, electric motors and enamel-coated coil wires are fundamental components of modern technology. These components enable electric motors to work powerfully and efficiently for various applications, which holds great significance in both industrial and everyday life. Enamel-coated coil wires increase the reliability and efficiency of these motors, making them indispensable power sources.