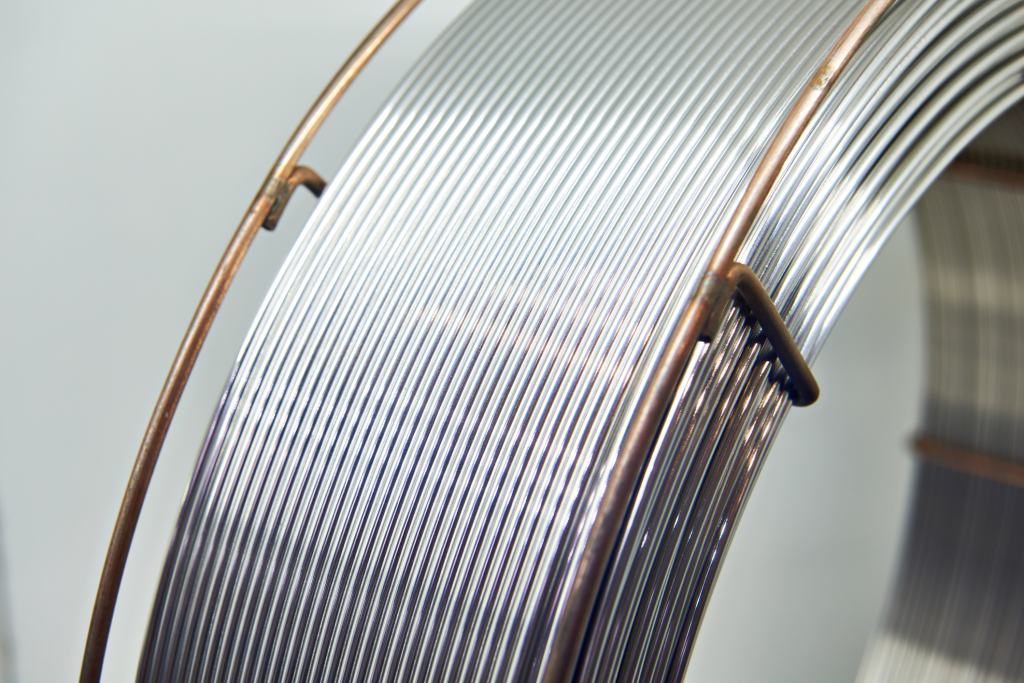

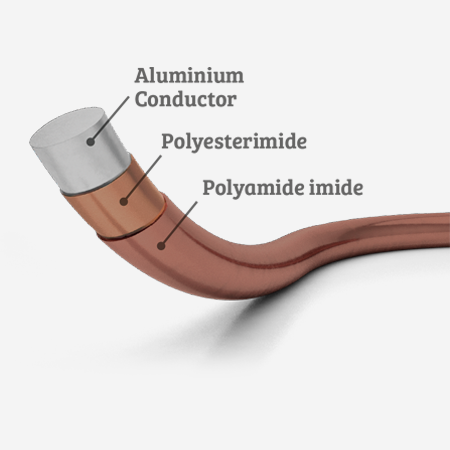

Aluminum enamel wire, also known as aluminum enamelled wire, is a type of wire used in electrical applications. It is made from a sturdy and durable aluminum alloy, and the surface of the wire is coated with an enamel insulation and protection layer. This coating enhances the electrical insulation and chemical resistance of the wire. Aluminum enamel wire is commonly used in electromagnetic devices such as inductors, transformers, and motors.

Here are some advantages of aluminum enamel wire:

1. Lightweight: Aluminum is a lighter metal compared to copper, making aluminum enamel wire lighter and easier to handle.

2. High Conductivity: Aluminum is a good conductor of electricity, allowing for efficient energy transmission.

3. Durability: The enamel coating protects the wire’s surface from scratches, chemical exposure, and abrasion.

4. Electrical Insulation: The enamel coating provides electrical insulation, preventing contact between bare conductors.

5. Low Magnetism: Aluminum enamel wire exhibits low magnetism, making it suitable for use in magnetic devices.

6. Thermal Conductivity: Aluminum’s good thermal conductivity ensures efficient heat dissipation.

Aluminum enamel wire is commonly used in electric motors, transformers, generators, inductors, and various other electrical devices. It serves as a fundamental component for the conversion and transmission of electrical energy.